By David L. Bristow, History Nebraska

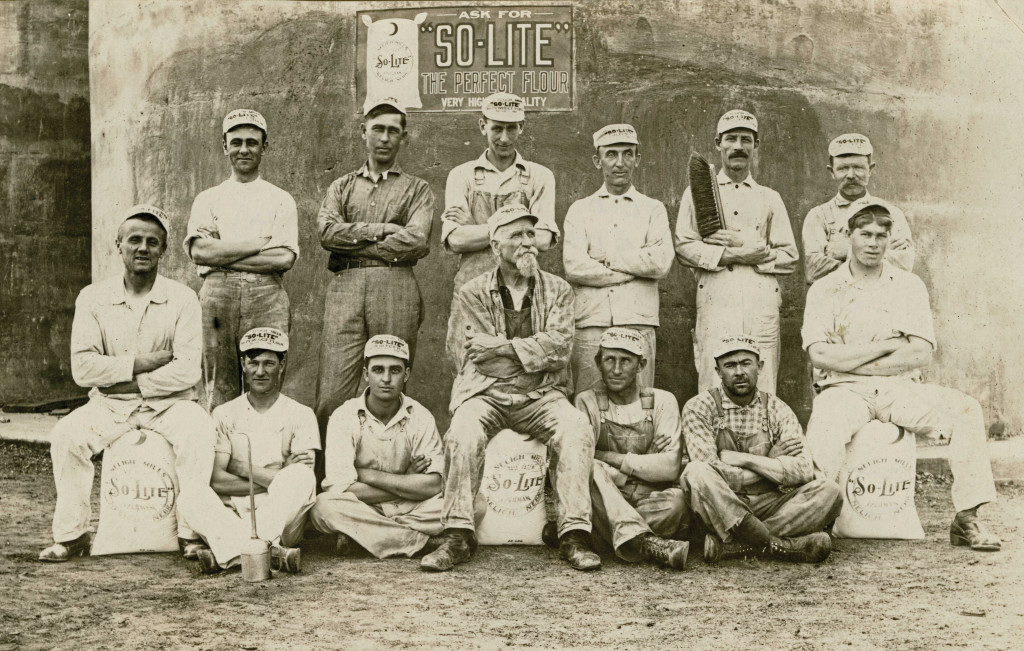

Neligh Mill, in the northeastern Nebraska town of Neligh, is a place where the past doesn’t feel all that long ago — as if the mill workers have gone for coffee and will be back shortly. The 19th century machinery is still in place, and longtime site supervisor Harv Ofe can tell you how it all worked. Yellowed notices and posters adorn the walls, and penciled graffiti shows the math of long-ago transactions and the dates of noteworthy local weather.

John Neligh began building the water-powered mill in 1873. Another local businessman completed the work and opened the mill the following year. Neligh Mill operated for nearly a century before becoming a state historical site maintained by History Nebraska.

Humans have been grinding grain into flour for thousands of years, mostly by hand. The oldest known mortars and pestles date to about 35,000 B.C. The use of millstones — also known as burrs — in water-powered gristmills dates back more than 2,000 years.

Neligh Mill, in other words, is based on ancient technology that was refined over the centuries. But it also reflects the rapid technological advances of the 19th and early 20th centuries as well as the unpredictable nature of the meandering, flood-prone Elkhorn River.

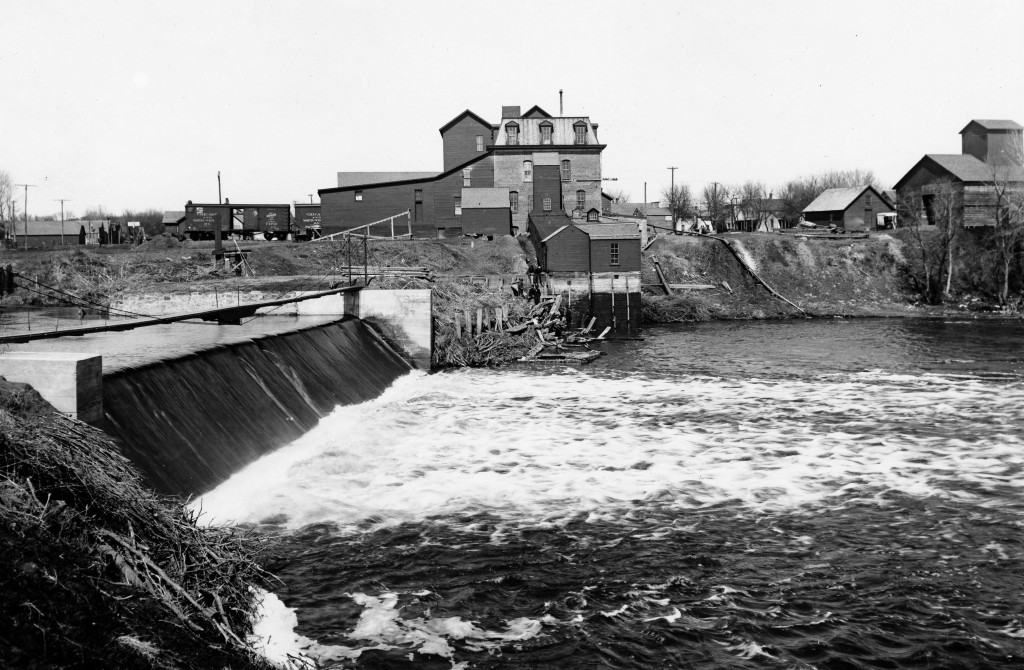

Using water power meant building a dam that was tall enough to have adequate “water head” — the height of water backed up behind the dam. The water was diverted into a flume where it turned a turbine that powered the mill.

Early photos show water pouring over a brush dam, a crude type of dam made by anchoring piles of brush with pilings and covering it with earth and rocks. Such dams were prone to being washed out by high water.

Neligh Mill replaced its brush dam with a concrete-based frame dam in 1903. The new dam was both stronger and taller, powering ever more machinery inside the mill and even providing power for the town’s first electrical grid.

But there was no taming the Elkhorn River, which was prone to floods, ice jams and burrowing muskrats that undermined dikes and dams. After a flood in 1915, the mill installed a large diesel engine to provide reliable power. Several years later, mill owners tried to return to water power, but gave up after a flood in 1920.

Meanwhile, new technology was changing the process of milling itself. After two millennia, the use of millstones became obsolete in the 1880s with the invention of steel roller mills. The rows of roller mills at Neligh may look old fashioned today, but at the time, they represented a big investment in the latest technology to greatly increase the mill’s output.

Neligh Mill produced its last flour in 1959. It continued grinding livestock feed for another 10 years before closing entirely. Fortunately for us, the owners left everything in place so that the mill could teach future generations about Nebraska’s agricultural history.